The Purafil PuraGrid® exceeds the new ISO-10121-3 testing classification for gas-phase air cleaning devices.

Purafil PuraGrid Filters for Australia

The Purafil PuraGrid® exceeds the new ISO-10121-3 testing classification for gas-phase air cleaning devices.

|

The PuraGrid® is a revolutionary filter that is designed to supply a large amount of chemical filtration with minimal amount of pressure drop.

This media delivery system offers increased operational performance and energy savings. The PuraGrid bridges the gap between Purafil’s existing line of filtration products, enabling a clean air solution for every application and market.

|

|

• Commercial buildings, hospitals, data centers, break rooms, and laboratories

• Corrosion control in refineries, petrochemical plants, power generation, and paper mills

• Semiconductor AMC filtration.

Talk to our Sydney Filter team to learn more about using Purafil PuraGrid filtration for your project >

Sydney: |

Ph : |

+61 3 8080 9935 |

aust.sales@windsorgroup.com.au |

Mob: |

+61 431 204 949 |

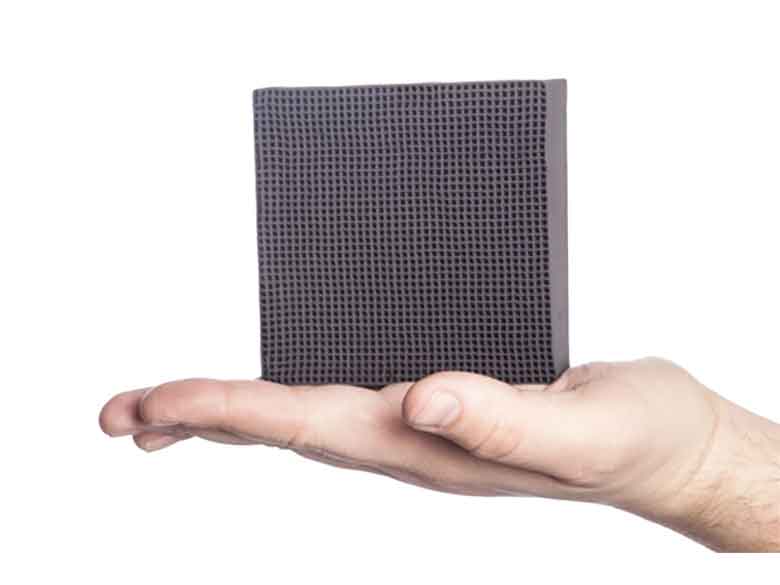

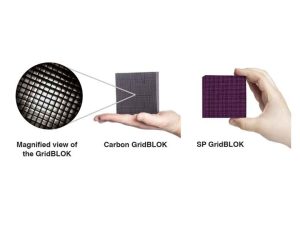

The GridBlok is a gas-phase air filtration medium in the form of an extruded monolithic block consisting of a large number of small, parallel cells or channels. The GridBlok is composed of essentially 100% adsorbent materials allowing the entire composite structure to function as a gas filter. Due to the

large number of cells in each GridBlok, the contact area between the adsorbent layer and the airstream that travels inside the cells is very large. Furthermore, the cells are parallel so that the flow is not obstructed and the pressure drop across the GridBlok is extremely low.

The cellular geometry of the extruded GridBlok provides a high surface area per unit volume important for proper impregnation of adsorptive materials. The size of the cells leads to turbulent flow and forces contaminated air into and through the gaspermeable cell walls of the GridBlok. It also provides the residence time necessary to assure optimum contact efficiency and the associated high initial and average removal efficiencies. As the air is forced through the GridBlok, removal of chemical contaminants takes place.

|

• No bypass – all of the air goes through the filter

• Low pressure drop – provides for energy savings

• Full utilization of the media – removal efficiencies and capacities comparable to granular media

• Self supporting – No Threat of Media Settling

• The GridBlok manufacturing is a closed-loop process and does not produce waste. The PuraGrid filter uses recycled frame and screen materials with a compressible partition made from 75%recycled post-consumer content.

Five GridBlok formulations are currently available in numerous sizes:

The Purakol® GridBlok, the Puracarb® GridBlok, Chlorosorb® GridBlok, the Puracarb® AM GridBlok and the IAQ GridBlok.

These formulations are effective against a number of gaseous contaminants and can be combined to provide the best performance in a wide range of applications. The performance of the GridBlok’s monolithic structure-based system is comparable to, and in some cases superior to, traditional packed-bed media systems.