Industrial Fans & Blowers

Fans are integral for many industrial processes, and also often work together with other equipment to provide airflow and pressure to key components, system cooling and material transfer.

Formerly IPSCO (1965-2012), our Auckland branch has more than 50 years’ experience designing, manufacturing, supplying and supporting fans and other air handling equipment in New Zealand and throughout the Pacific area.

We are the exclusive Australasian licensee of The New York Blower Company who maintain one of the largest ranges of catalogued industrial fans. Our long-standing relationship with NYB has given us the opportunity to supply best in class fans to New Zealand and the World.

More information can be found at their website: www.nyb.com/ >

You can rest assured, our quality control procedures and excellent after sales service make Windsor fans the best choice for dependability and long service life.

A wide range of efficient fans with aerofoil, laminar, backward curved and radial tipped blades for low noise levels & high efficiency. Suitable for VAV(variable air volume) control

Custom engineered fans for materials handling, process exhaust air and high temperatures. Typically these use radial tip and radial blade designs. For everything from light dust to corrosive air applications.

Our team of engineers can provide on-site assessment of your fan problems, repairs to existing equipment, re-powering of old fans with New York Blower impellers and shafts, and full servicing of fan and filter systems.

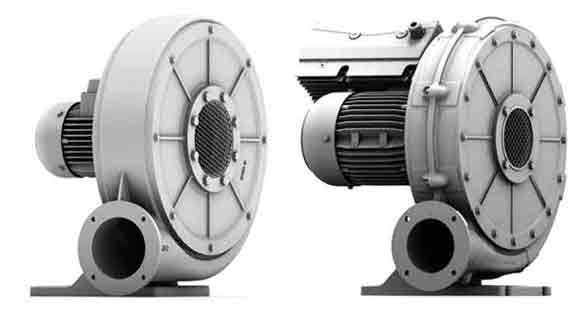

Packaged "plug and play" units available on indent from various brands including Elektror airsystems gmbh and Sodeca. Typically these blowers are direct driven and include standard metric frame motors for a large range of applications and performances.

Optimized for high static pressure systems, where conventional fans might run out of breath.

Materials handling, process exhaust air, high temperature applications.

Normally these fans use radial tip and radial blade.

Available in special configurations for highly corrosive air applications.

Manufacturing processes create complex problems which we solve by implementing a custom engineered fan solution. Typically, these applications are boilers, steel mills, pollution control systems such as baghouses, high-pressure systems such as diary product spray driers or any other processes requiring very high airflows and pressures.