Liquid Filtration

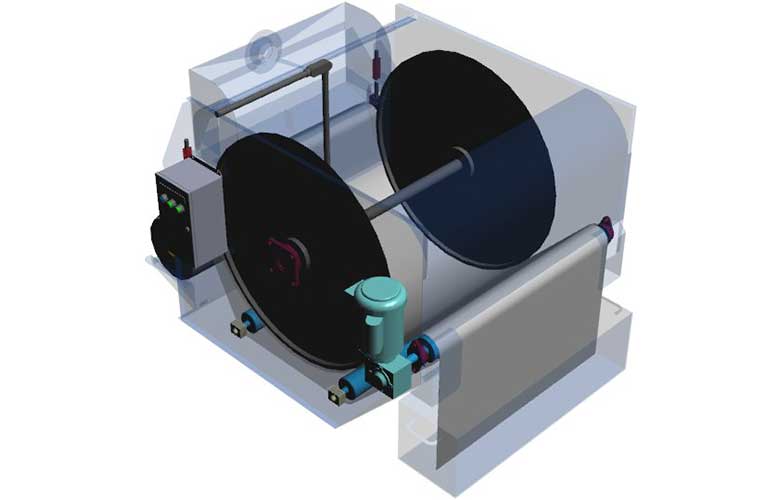

The K Factor Filter is a fully automatic and self-cleaning industrial liquid filtration system, engineered and designed to suit most applications in a number of industries where removal of solids from liquids is required.

A number of different construction types and sizes are available.

Each application has its own challenges and requirements. We work closely with each customer to insure that their specific needs are met. In each of these applications the filter offers a significant range of features and benefits.

The flow of liquid enters the K FACTOR FILTER into the header box and evenly distributes the flow across the media via the shearing nozzle.

This nozzle creates a shearing action that pushes the solids along to the bottom area of the filter and allows the clean liquid to go through the media.

The flow of liquid is contained within the two sealing wheels allowing the media to trap the solids and the clean to return to the process.

As the liquid level in the filter between the two sealing wheels rises it will be sensed by a level probe and initiate a cleaning cycle.

The clean filtered liquid return to the process.

Note: The shearing action of the filter is the key feature in media usage. The solids are not pressurized into the media which extends the life of the media and allows for greater solids removal.

Removes most solids down to 5 microns regardless of

▪ Shape

▪ Specific gravity

▪ Concentration of dirt

▪ Type

The key feature of the K Factor Filter is the shearing action produced by the unique shearing nozzle. The liquid to be filtered flows into the header box and then is evenly distributed across the filter media via

“The Shearing Nozzle”

The filter media is on a steep slope to create the shear. The flow of liquid from the nozzle impacts on the media creating “The Shearing Action”. The unwanted solids are pushed to the bottom of the sealed basin and the clean filtered liquid flows through the selected filter media. This unique feature reduces the footprint, reduces the amount of media used and improves the filtration.

The shearing nozzle is situated close to the filter media to create a shearing action on impact. The flow enters the header box and impacts on the media to push the solids to the bottom of the sealed basin to:

Please contact our Wellington office for further assistance >